Engineering

A.W. Mercer Inc. boasts an engineering department with over 100 years of combined design, manufacturing and production experience. We proudly offer our customers the following engineering services; Design collaboration, Prototype design, Rapid prototyping, Reverse engineering

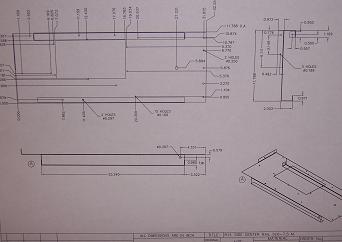

A.W. Mercer engineers use SolidWorks™, a 3D Mechanical Design and 3D CAD Software. This powerful engineering program allows our staff to:

- Exchange drawings and sketches with customers

- Use 3-D customer designed models

- Unfold models to make individual components

- Reduce the amount of customer engineering time

Our engineers are also an excellent resource and extension of our customers' engineering staffs. We offer the following value added services;

- Design and fabrication changes to enhance product quality and integrity

- Rapid prototype fabrication to assure product quality and customer acceptance

- Collaborate with customers to produce lowest cost, highest quality products

- Translate customer needs to quality products assuring both integrity and superiority

We can accept files - full scale and dimensionally accurate - on CD-ROM and high-density floppy diskette (3½") in the following formats: .sldprt, .sldasm, .slddrw, .dxf, .dwg, .x_t, .igs, .step, .prt, .(CadKey). We can also accept hard copy of any drawing or sketch via fax @ 610-367-7491. Files can be uploaded or e-mailed to sales@awmercer.com.